The design, installation and operating requirements for animal house washers should take into account various changing constraints such as:

- the relevance of investment and the “return on investment” and the payback time,

- the defined level of the health management programme, the expected overall performance and consistency of processes, including the operational control of cross-contamination risks,

- the optimisation of operating costs: workforce requirements, washing capacity per unit of time with respect to the washing load: personnel availability, capacity per washing cycle, absence of flow bottlenecks, outage management, etc.

- the implementation of the site HSE programme: healthy and safe working environment and practices, preventing work-related musculoskeletal disorders, requirements in the areas of HSE and working conditions: safe and healthy workplace (including risk of exposure to allergens, vapours, aerosols and biological agents), avoidance of repetitive handling and load carrying operations, etc.

- sustainable development criteria: controlled / reduced energy and water consumption and waste / effluent production.

We should therefore keep providing the most performant technical solutions available in order to optimise the efficacy of washing and disinfection processes, maximising their contribution to the quality of the health management programme, in response to regulatory requirements as well as to the expected performance of research activities:

- contribution to the control and quality of animal models and studies,

- compliance with the animal welfare and 3Rs regulatory requirements.

In that context and in response to these challenges, all potentially applicable solutions should be assessed and compared in order to select then deploy the most appropriate and best performing ones.

Technical choices regarding washing and disinfection equipment for SPF and SOPF rodent animal units are decisive success. Hence, ‘‘washer-disinfector’’ solutions may represent a major improvement opportunity when creating or renovating an animal facility.

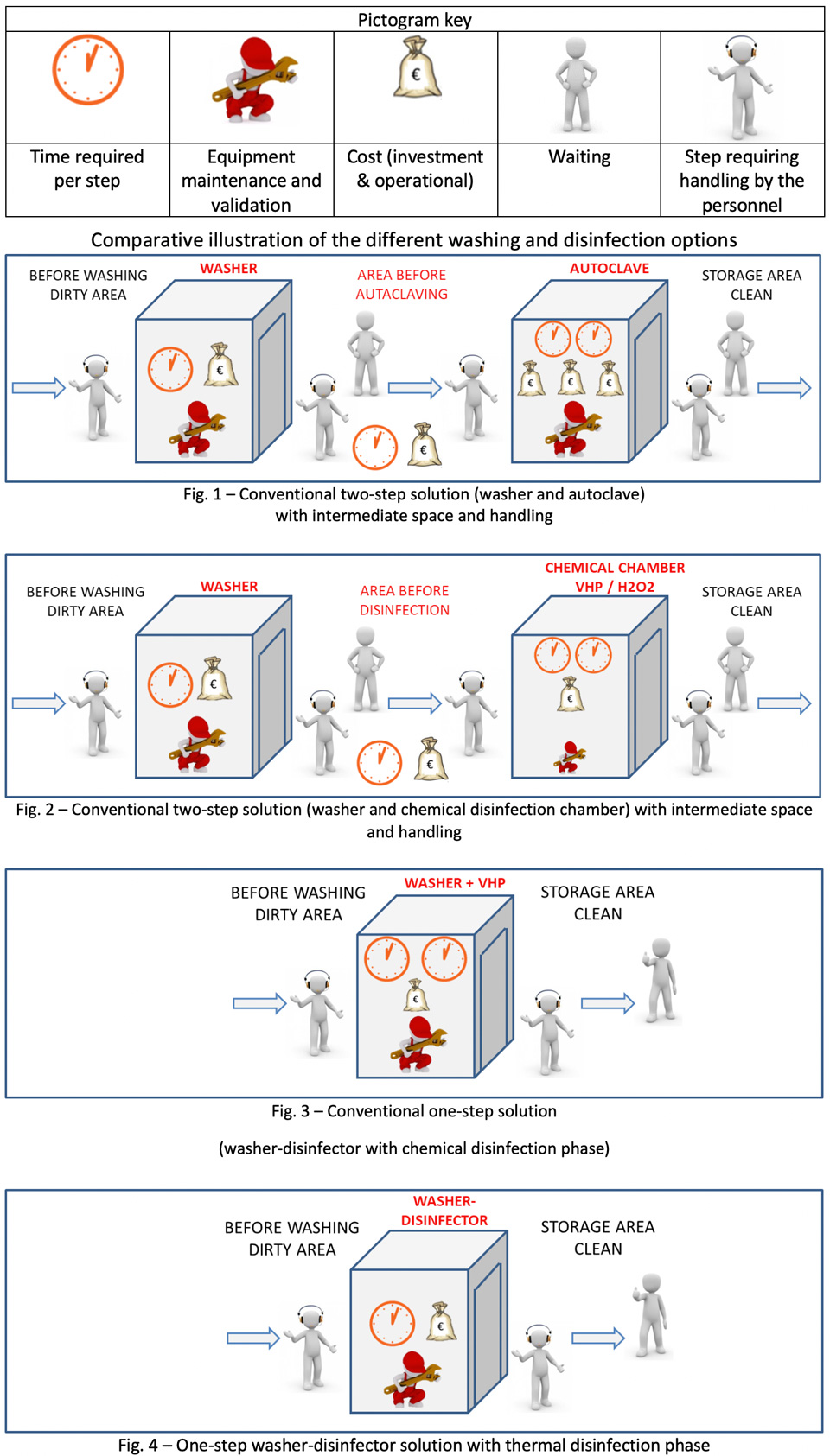

The following drawings illustrate several washing and disinfection solutions at washing area and barrier level

A “washer-disinfector” is designed to accomplish a thermal disinfection phase either at the time of a high-temperature pre-rinsing operation (see below: “A0” value adopted) or by the injection of steam at the end of the programme. Such a technical solution is compatible with short-cycle times and allows validating thermal disinfection with defined loads in order to guarantee process suitability and robustness.

Washer-disinfectors are commonly used in hospital environments, according to the applicable ISO standards, such as ISO 15883-1 “Washer-disinfectors – General requirements, terms and definitions and tests”.

The washing phase must first ensure a high-quality washing, achieving a reduction in the equipment’s bio-burden, through optimum / synergic combination of the four factors described in the Sinner circle and those applicable to washer efficiency.

One disinfection option would be to inject steam at the end of the cycle. This option has its advantages but particular attention must be paid to the satisfactory diffusion of the steam to every point of the load and of the washer’s chamber. It also requires a steam generator.

Another particularly interesting option is disinfecting at the time of pre-rinsing, by spraying high-temperature water for a given plateau time, ensuring the defined temperature and time at every point of the load and of the chamber. This “temperature / time” combination gives an “A0” value, which is a physical parameter expressing an equivalence between time and a given temperature and denoting an inactivation of the microorganisms by thermal disinfection in a washer-disinfector.

More detailed information can be provided on request.

Allentown’s VPS department is at your disposal to conduct a personalised study in order to assess the best suited solution to your situation, needs and constraints.